SPP in the Food and Beverage Industries

For almost 38 years now, SPP CORPORATION has

been designing, fabricating and constructing a

wide range of process equipment for the food,

beverage, personal care. Chemical, and

pharmaceutical industries. Using stainless or other

special grade materials, SPP custom-builds tanks,

mixers, cookers, vats, silos, pressure vessels,

blenders, and conveyors of various sizes and designs

to serve the unique process needs of our customers.

Together with export works in the Asian region, we

are proud to have supplied major multinational

companies such as Coca-Cola, Pepsi Cola, Nestle,

Kraft, Dole, Procter & Gamble, Johnson & Johnson,

Wyeth, Hoechst, Mead Johnson, Tetra Pak, Alfa Laval

and local giants such as San Miguel Corp., United

Laboratories, URC, RFM, Magnolia and Sugarland.

Customer Satisfaction

Primarily a service organization, SPP is built

around the principle of satisfying our

customers. Our commitment to produce

equipment and services that answer the needs of

our customers is fully backed by solid warranty.

SPP systems and procedures have been

streamlined to ensure client requirements are

followed from order taking and production delivery

and commissioning.

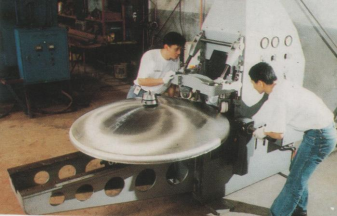

People and Machine Hand-in-Hand

From experienced design engineers and CAD operators, skilled project managers and sales engineers, to qualified welders, the people of SPP are regarded as the company’s most vital resource. Equipped with modern engineering tools and the latest in metal finishing technology, our engineers and craftsmen manufacture products meeting global engineering and process standards such as ASME, DIN, and GMP.

Training is vital part of SPP’s business philosophy ensuring that workmen receive both skills and values training to upgrade their competence.

Quality Assurance

Conforming to ISO 9002 standards, quality assurance is an integral process in our work flow. Quality hold points and inspections done from design, material purchase, fabrication, delivery to installation ensure engineering and workmanship standards are met.

Welders are periodically tested and qualified to ensure a consistent high level of workmanship